The right choice, made in France

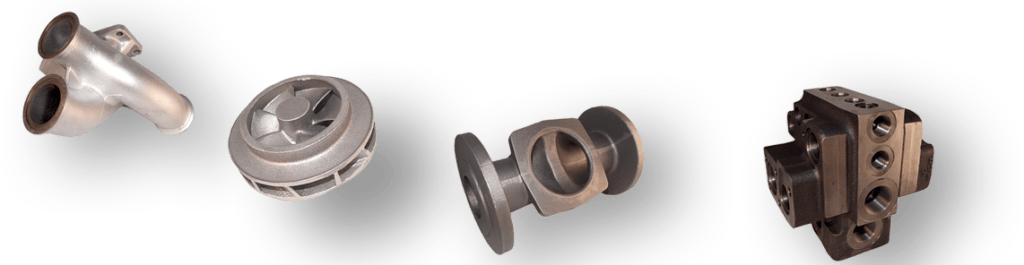

Nodular iron castings

Lamellar graphite iron castings

Special iron castings

DESIGN AND CO-DESIGN DEPARTMENT

Fonderies Nicolas and its design department help you to carry out your project.

Research and development, simulations: We are there to help you from the genesis to the realization of your project.

Co-conception is our key word for a shared success.

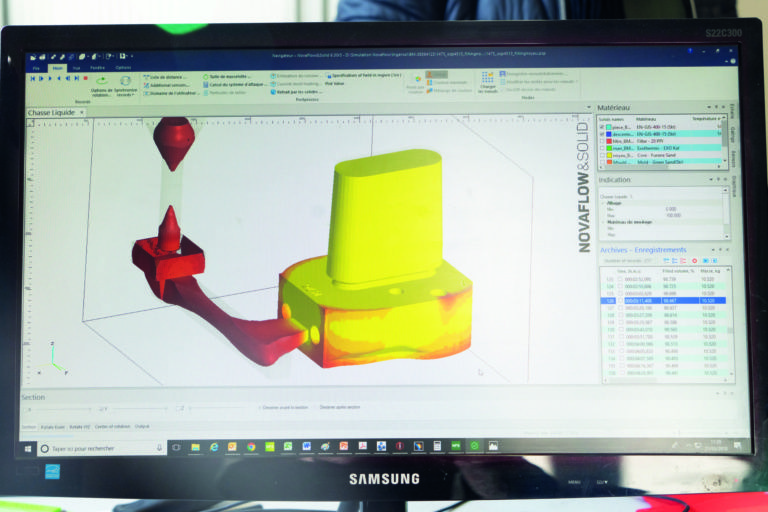

RESEARCH AND DEVELOPMENT

Thanks to our various equipment: CAD, foundry simulation software or plastic 3D printing, we are able to make prototypes.

We also rely on our partners CRITT MDTS and Platinium 3D regarding R&D tools.

Our metallurgical lab implements and ensures the follow-up of new grades. We constantly aim at meeting new standards.

RAPID PROTOTYPING

Fonderies Nicolas is the co-owner of a company from Charleville-Mézières which makes moulds and sand cores with additive manufacturing.

This advanced technology speeds up the industrialization stages while reducing production costs.

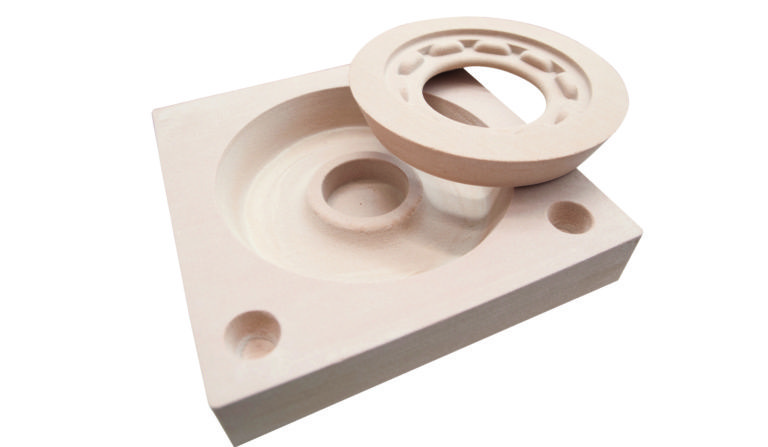

PATTERN-MAKING

Fonderies Nicolas make moulds specifically designed to the quantity and the typicity of the parts.

They can be made of aluminum, resin, plastic or wood and we can also adjust to existing moulds.

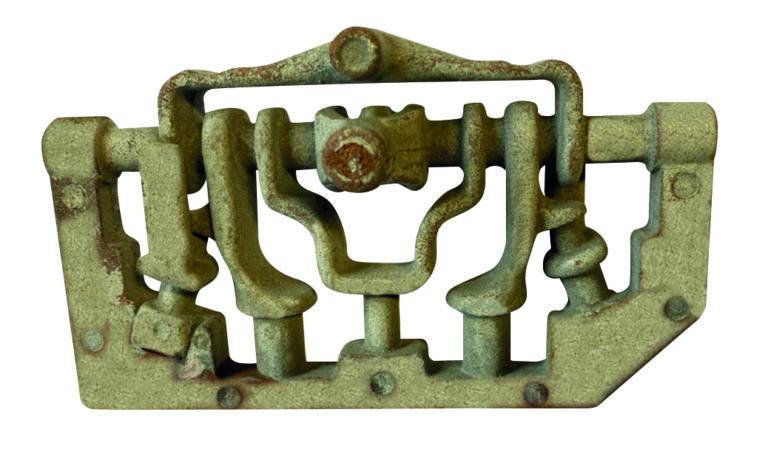

CORE MAKING

Our core making automated machines driven by experimented teams, cold box and hot box facilities and Croning & Ashland processes allow an outstanding core making while reducing significantly the impact of machining.

Our speciality: pieces with very specific shapes.

Fonderies Nicolas uses clean resins in compliance with environmental standards.

MOULDING

Fonderies Nicolas has a moulding site with horizontal moulding machines (Green sand process – 100 moulds per hour) completely automated which allow speed and flexibility.

Our sand is constantly recycled for optimal environmental protection.

MELTING

We make :

- Ferritic and pearlitic nodular iron

- Grey iron

- Malleable iron

- Allied cast iron

- ADI cast iron

- Low temperature cast iron EN GJS 350.22

- High-Silicon content castings

SHAKEOUT SHOT PEENING SANDING

The shakeout which is the first stage after the pouring one is made automatically.

The robot-assisted shot peening suitable for any size and geometry of parts avoids any distortion.

The sanding process aims at enhancing surface finishes, our sand blasting machines are particularly suitable for the cleaning of the hoses of hydraulic parts.

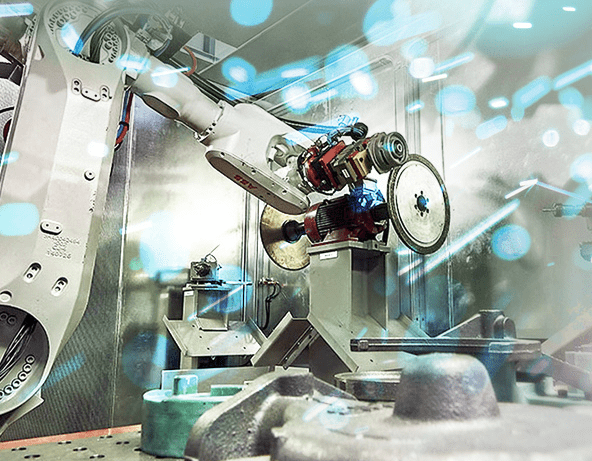

DEBURRING

For larger parts and large series, Fonderies Nicolas use a robot cell. Being much more suitable for heavy parts, this ABB robot proves to be much quicker and more effective while protecting the physical integrity of operators.

For small pieces or small series, Fonderies Nicolas favour manual deburring.

HEAT TREATMENT

Our furnace has a five-ton capacity.

This process which is performed in our workshop is to enhance the mechanical properties of the parts.

MACHINING

As part of their expansion, Fonderies Nicolas has just acquired a machining subsidiary.

The production equipment which includes 4 machining centers, 6 numerically controlled lathes, different models of drills and a 3D machine for tridimensional is run by an experimented team.

SURFACE TREATMENT

For optimum reliability, Fonderies Nicolas control several processes for the highest finish quality and protection:

- Zinc plating

- Painting (liquid and epoxy)

- Electrodeposition

- Zinc coating

- And any king of adapted treatment requested by the customer.

ASSEMBLY, STORAGE AND LOGISTICS

As assembly is carried out in our workshop, our teams can include any other components.

To shorten manufacturing time and minimize costs, Fonderies Nicolas have a high capacity of storage.

In addition to this, we ensure the packaging and manage the logistics to provide our customers a full service.