The right choice, made in France

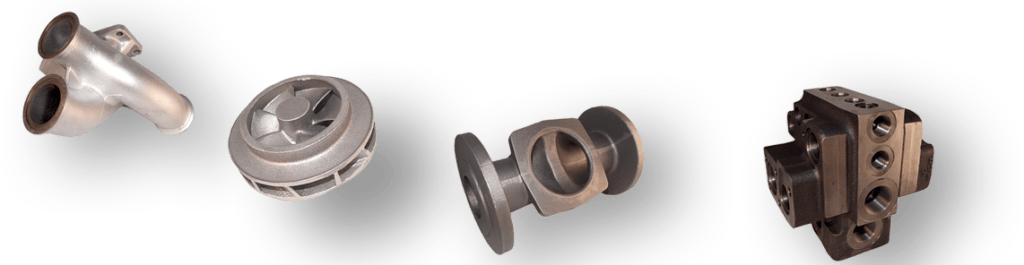

Nodular iron castings

Lamellar graphite iron castings

Special iron castings

MEANS OF PRODUCTION

CORE MAKING

3 automatic core making machines

Cold box facilities (H5 – H12 – H16) and hot box facilities

Croning & Ashland processes

Cold box facilities (H5 – H12 – H16) and hot box facilities

Croning & Ashland processes

AUTOMATIC IMPACT MOULDING

Small and medium series from 1 to 10 000 pieces

400 x 600 x 150 x 150 frames.

400 x 600 x 150 x 150 frames.

MELTING

2 medium-frequency induction furnaces (1 metric ton each)

SHOT PEENING

Drum blast machines

Sand blast machines

Sand blast machines

TESTS AND INSPECTIONS

Thermal and spectrometric analyses

Mechanical tests, brinell hardness tests, microstructure, magnetic crack detection, ultrasonic tests

Inspection on 3D-machine

Contaminant research

Mechanical tests, brinell hardness tests, microstructure, magnetic crack detection, ultrasonic tests

Inspection on 3D-machine

Contaminant research

HEAT TREATMENT

Capacity : 5 tons

Tempering, ferritizing, stabilization, pearlitization (electric furnace with automatic regulation et controlled atmosphere)

Tempering, ferritizing, stabilization, pearlitization (electric furnace with automatic regulation et controlled atmosphere)

TRIMMING WITH HYDRAULIC WEDGE

INTEGRATED PATTERN-MAKING

Wood, resin and aluminium pattern-making equipment.

INTEGRATED MACHINING

with our subsidiary

- 6 NCC LATHES

Capacity between centers 0 à 600 mm

- 4 MACHINING CENTERS, ONE OF WHICH WITH A 4th AXIS

- TRADITIONAL MACHINE

Drilling, milling and tapping machines …

- 3D MACHINES FOR TRIMENSIONAL CONTROL

Capacity between centers 800 x 500 mm